DESIGNING

FOR SAFETY

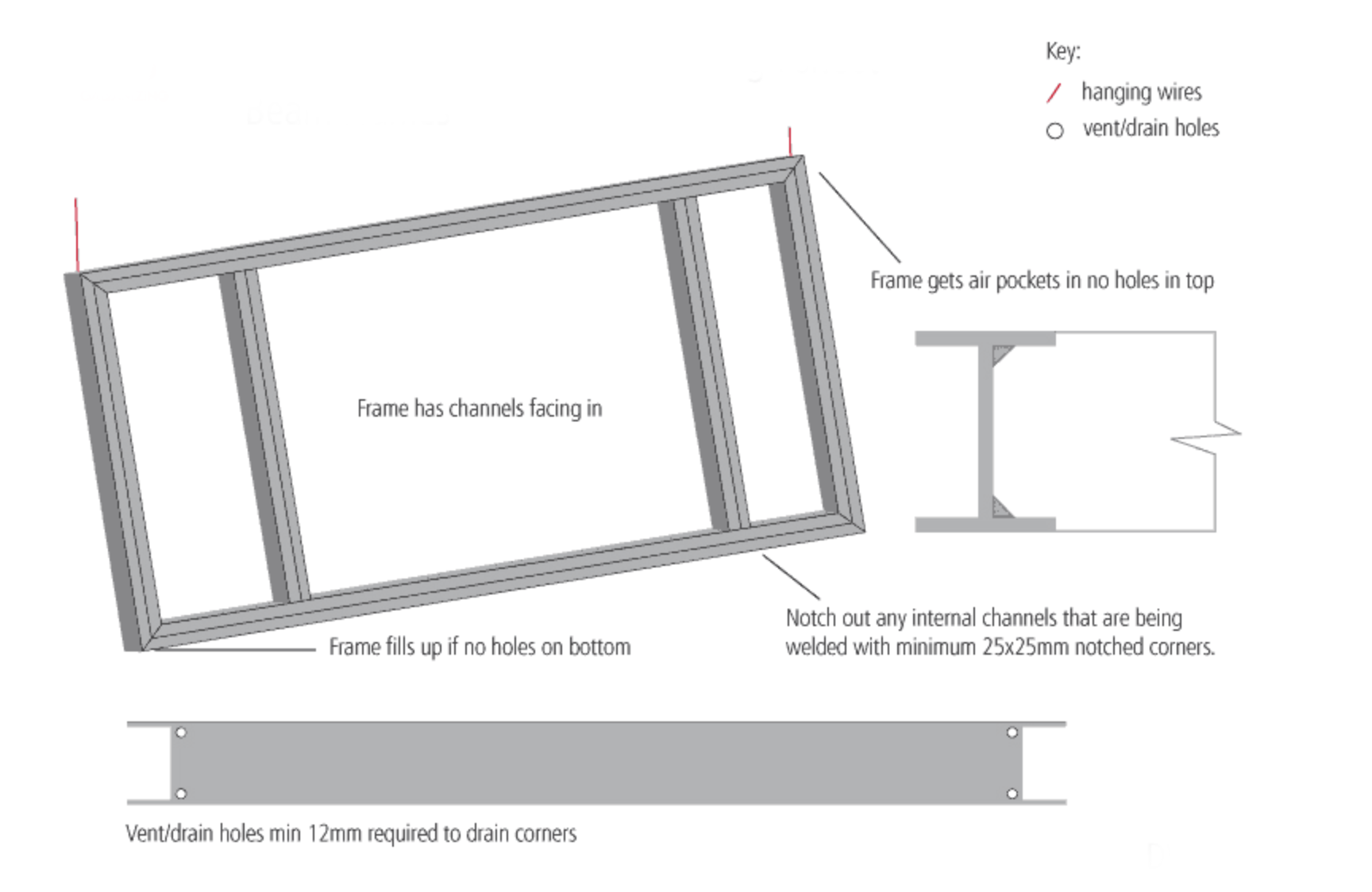

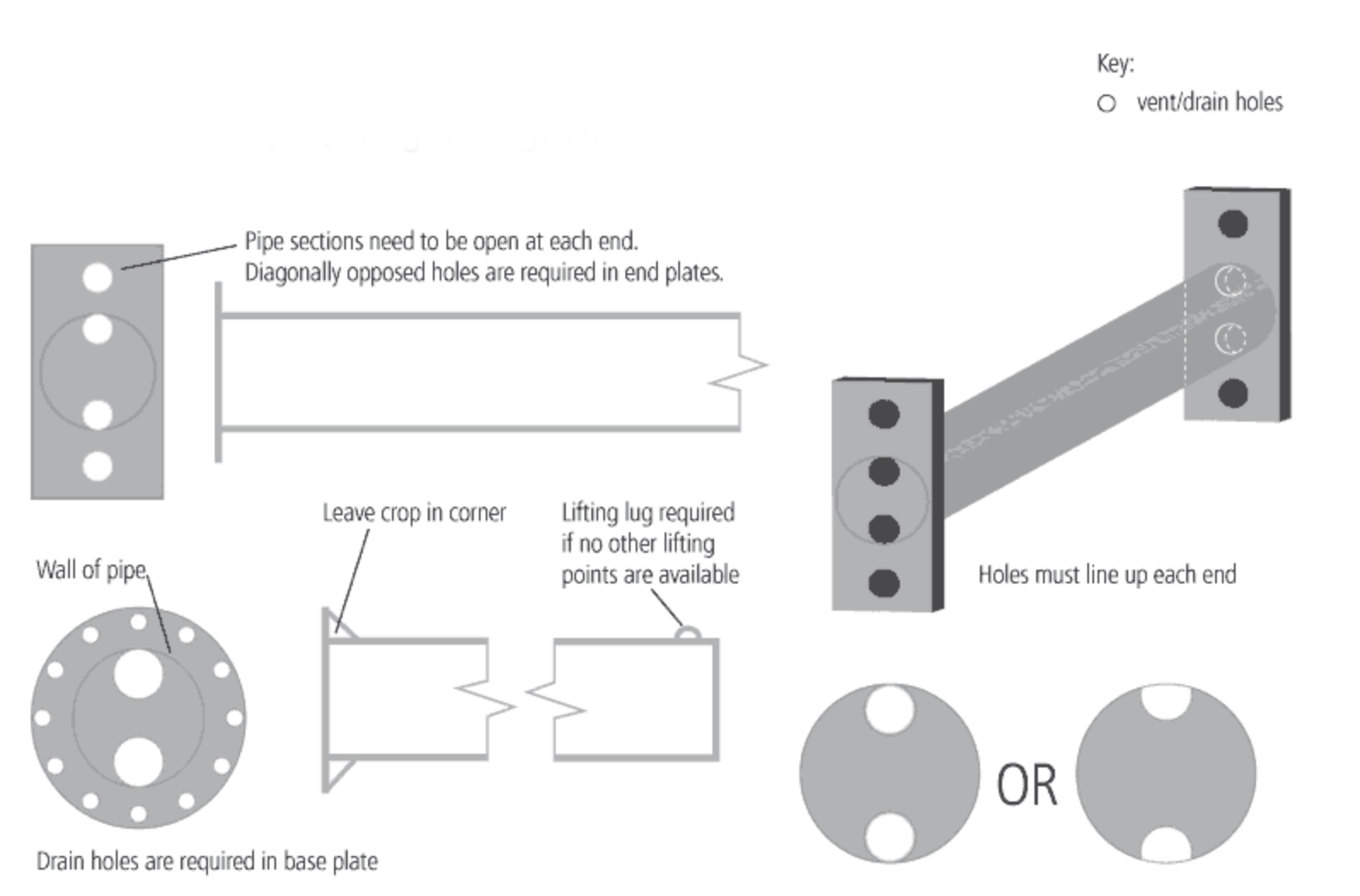

Ensure that any vessels or hollow structures containing enclosed sections have adequate venting during galvanizing.

When exposed to galvanizing temperatures, any moisture present in closed sections can rapidly turn into superheated steam,

generating explosive forces unless properly vented to the atmosphere. Proper venting is essential for the safety of galvanizing personnel, equipment, and the work being galvanized. It also ensures that the entire internal surface of the work is correctly galvanized and fully protected.

For closed vessels not meant to be galvanized inside, such as certain types of heat exchangers, snorkel-type vent pipes long enough to extend above the level of pickling, fluxing, and galvanizing baths when fully immersed must be provided.

The specific venting requirements should be discussed with the galvanizer to ensure safety and proper galvanizing results.

Galvanizing service hole design sheet -

RHS section (straight)

Channel Frames 2 Dimensional

Beam Frames

Beam and Universal Columns

Channel with End Plates

Tubular Frames

Pipe Straight Length

Plates Floor Plates

Gates and Fence Panels

Boat Trailer Preperation

Box Trailor Preparation

Handrails

Post and Base Plates

Roof Rack

Design for Galvanizing

To download poster for veiwing or

print please click the download button.